Brief Introduction

Since the first introduction as cutting tools materials, cubic boron nitride (CBN) has gradually became the preferred solution for difficult machining materials. Its application fields include hard steel, cast iron, high-temperature alloy and powder metallurgy materials.

With high thermal stability, CBN inserts can resist the high temperature of 1300℃. At the same time, it can also maintain its cutting-edge performance. This is the reason that CBN inserts can provide a long time stable tool life and high machining efficiency. Furthermore, it can ensure to get high surface roughness and this is the reason for replacing grinding by turning.

Product Application

|

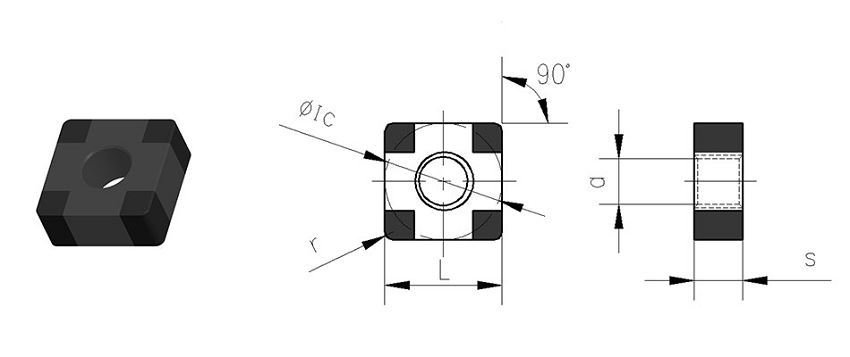

ISO |

Dimension |

Cutting Edge Form |

Grades | |||||||

|

ISO |

L |

φIC |

S |

d |

r |

S1 |

S2 |

X2 |

X3 |

|

|

SNMA090404 |

9 |

9.525 |

4.76 |

3.81 |

0.4 |

T01020 T01025 T02020 S02025 S02030 |

|

|||

|

SNMA090408 |

9 |

9.525 |

4.76 |

3.81 |

0.8 |

|||||

|

SNMA090412 |

9 |

9.525 |

4.76 |

3.81 |

1.2 |

|||||

|

SNMA120404 |

12 |

12.7 |

4.76 |

5.16 |

0.4 |

|||||

|

SNMA120408 |

12 |

12.7 |

4.76 |

5.16 |

0.8 |

|||||

|

SNMA120412 |

12 |

12.7 |

4.76 |

5.16 |

1.2 |

|||||

|

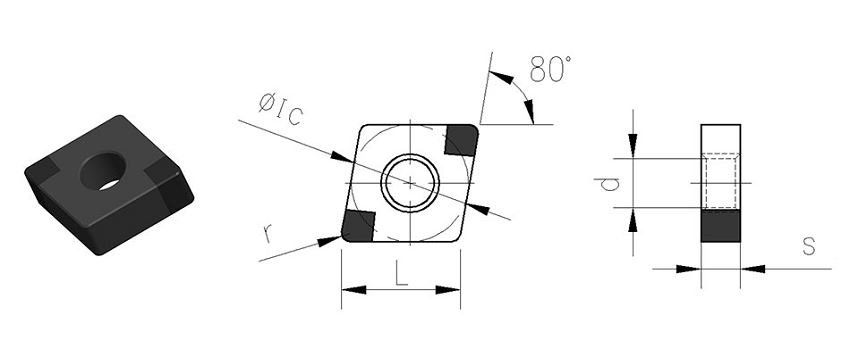

ISO |

Dimension |

Cutting Edge Form |

Grades | |||||||

|

ISO |

L |

φIC |

S |

d |

r |

S1 |

S2 |

X2 |

X3 |

|

|

CNMA120404 |

12 |

12.7 |

4.76 |

5.16 |

0.4 |

T01020 T01025 T02020 S02025 S02030 |

||||

|

CNMA120408 |

12 |

12.7 |

4.76 |

5.16 |

0.8 |

|||||

|

CNMA120412 |

12 |

12.7 |

4.76 |

5.16 |

1.2 |

|||||

|

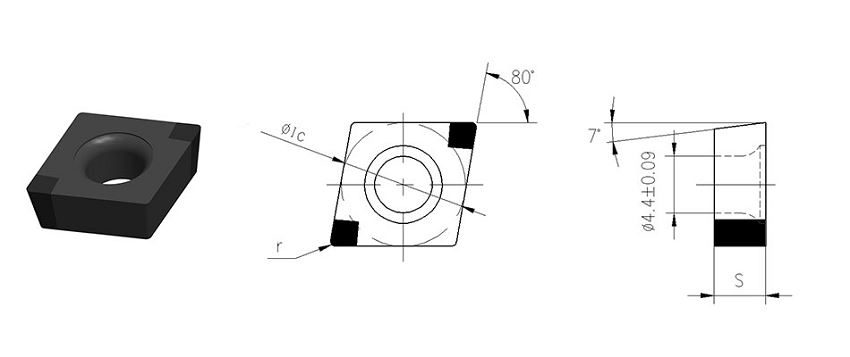

ISO |

Dimension |

Cutting Edge | Grades | |||||||

|

ISO |

L |

φIC |

S |

d |

r |

S1 |

S2 |

X2 |

X3 |

|

|

CCGW09T304 |

9 |

9.525 |

3.97 |

4.4 |

0.4 |

T01020 T01025 T02020 S02025 S02030 |

||||

|

CCGW09T308 |

9 |

9.525 |

3.97 |

4.4 |

0.8 |

|||||

|

CCGW120404 |

12 |

12.7 |

4.76 |

5.56 |

0.4 |

|||||

|

CCGW120408 |

12 |

12.7 |

4.76 |

5.56 |

0.8 |

|||||

|

CCGW120412 |

12 |

12.7 |

4.76 |

5.56 |

1.2 |

|||||

|

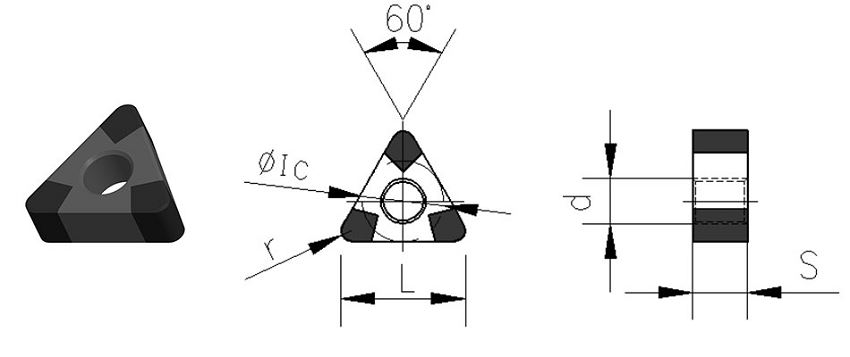

ISO |

Dimension |

Cutting Edge Form | Grades | |||||||

|

ISO |

L |

φIC |

S |

d |

r |

S1 |

S2 |

X2 |

X3 |

|

|

TNMA160404 |

16 |

9.525 |

4.76 |

3.81 |

0.4 |

T01020 T02020 S01020 S02020 |

||||

|

TNMA160408 |

16 |

9.525 |

4.76 |

3.81 |

0.8 |

|||||

|

TNMA160412 |

16 |

9.525 |

4.76 |

3.81 |

1.2 |

|||||

|

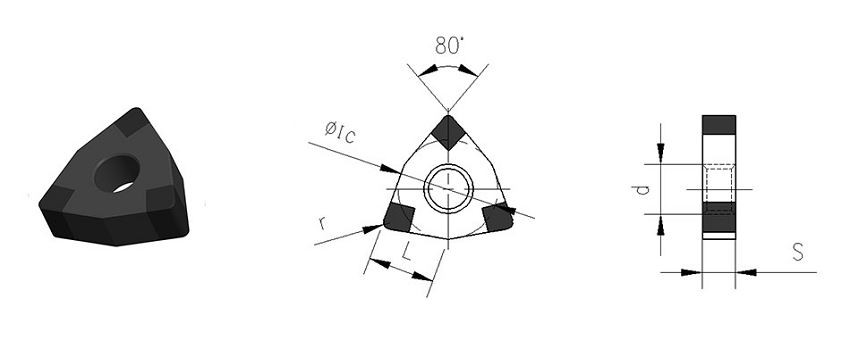

ISO |

Dimension |

Cutting Edge Form |

Grades | |||||||

|

ISO |

L |

φIC |

S |

d |

r |

S1 |

S2 |

X2 |

X3 |

|

|

WNMA060404 |

6 |

9.525 |

4.76 |

3.81 |

0.4 |

T01020 T01025 T02020 S02025 S02030 |

||||

|

WNMA060408 |

6 |

9.525 |

4.76 |

3.81 |

0.8 |

|||||

|

WNMA060412 |

6 |

9.525 |

4.76 |

3.81 |

1.2 |

|||||

|

WNMA080404 |

8 |

12.7 |

4.76 |

5.16 |

0.4 |

|||||

|

WNMA080408 |

8 |

12.7 |

4.76 |

5.16 |

0.8 |

|||||

|

WNMA080412 |

8 |

12.7 |

4.76 |

5.16 |

1.2 |

|||||

|

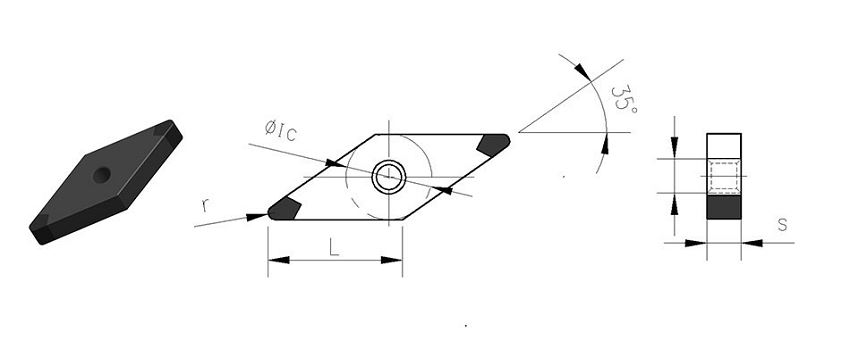

ISO |

Dimension |

Cutting Edge Form | Grades | |||||||

|

ISO |

L |

φIC |

S |

d |

r |

S1 |

S2 |

X2 |

X3 |

|

|

VNMA160404 |

16 |

9.525 |

4.76 |

3.81 |

0.4 |

T01020 T02020 S01020 S02020 |

||||

|

VNMA160408 |

16 |

9.525 |

4.76 |

3.81 |

0.8 |

|||||

|

VNMA160412 |

16 |

9.525 |

4.76 |

3.81 |

1.2 |

|||||

|

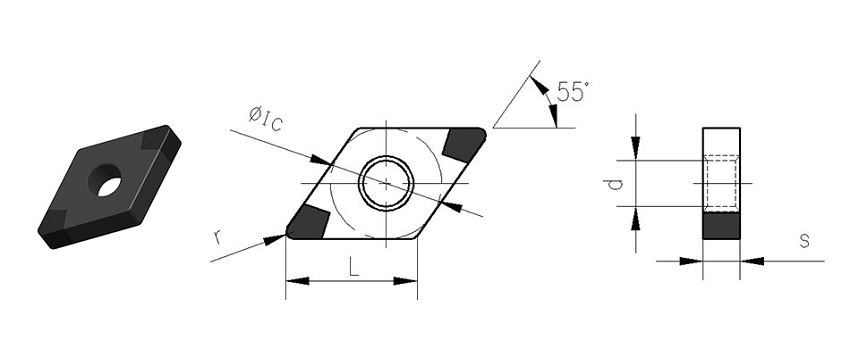

ISO |

Dimension |

Cutting Edge Form |

Grades | |||||||

|

ISO |

L |

φIC |

S |

d |

r |

S1 |

S2 |

X2 |

X3 |

|

|

DNMA110404 |

11 |

9.525 |

4.76 |

3.81 |

0.4 |

T01020 T01025 T02020 S02025 S02030 |

||||

|

DNMA110408 |

11 |

9.525 |

4.76 |

3.81 |

0.8 |

|||||

|

DNMA110412 |

11 |

9.525 |

4.76 |

3.81 |

1.2 |

|||||

|

DNMA150604 |

15 |

12.7 |

6.35 |

5.16 |

0.4 |

|||||

|

DNMA150608 |

15 |

12.7 |

6.35 |

5.16 |

0.8 |

|||||

|

DNMA150612 |

15 |

12.7 |

6.35 |

5.16 |

1.2 |

|||||

Related Products